Although modern solutions of disinfection have guaranteed the sanitization of our environment with Best UV disinfection system, there has been a few alternatives which can also eradicate pathogens and fumigate the precipice.

The traditional method to controlling

such infection has been to implement cleansing and disinfection regimes. This

targeted technique may be sufficient to daily manage the contamination, however

does not always remove all environmental micro-organisms and, in some

instances, they are able to persist in factories for numerous years.

Let’s look into a few such disinfection systems which doesn’t use Best UV disinfection system

·

Chemical fogging

Making

use of chemical disinfectants to manufacturing regions as fogs or mists is

a method used mechanically within the food enterprise. The reason is to

create and disperse a disinfectant aerosol to reduce the numbers of airborne

micro-organisms and additionally to apply disinfectant to surfaces that can be

hard to reach.

·

Vaporized hydrogen peroxide

Due to

its rapid degradation into innocuous byproducts, fumigation with VHP is a

technique that has been widely used for disinfection of the pharmaceutical

environment, including cleanrooms and production filling lines, and therefore

may be an alternative to chemical fogging for the food industry.

·

Ozone

High

reactivity, penetrability and spontaneous decomposition into a non-toxic

product make ozone a feasible disinfectant for use in food production areas.

Due to its reactive, unstable nature, ozone is produced based on the factor of

use. Ozone mills efficaciously skip air via a high-strength source, consisting

of UV or corona eradication within the system, which ends up in the formation

of ozone.

·

Chlorine dioxide

Clo2 gas

is considered environment-friendly because it rapidly breaks down into

innocuous sodium salts. It's far volatile and therefore is generated at its web

page of use by means of numerous chemical and electro-chemical strategies.

·

Titanium dioxide coating

Surface

coatings have been developed using nanotechnology that make surfaces easier to

clean or ‘self-cleaning.’ One coating, widely used due to its non-toxicity,

chemical stability and capability for repeated use without the loss of

catalytic activity, is titanium dioxide (TiO2).

·

Ionization

This involves air that clearly contains moisture, being handed over ionizing tubes emitting a high voltage discharge, such as a corona, to supply positively and negatively charged ions, which include hydroxyl radicals (oh-) and exceptional oxide anions (o2-).

How is the Best UV light for HVAC different from these methods?

·

Ultraviolet light

Conveyor

belt structures and barrier tunnels were evolved and portable UV lamps have

been designed to allow disinfection to be executed on surfaces where a dry

chemical-unfastened disinfection method is required.

·

Titanium dioxide/ultraviolet light/ Best UV light for HVAC

Floor coatings have evolved the usage of nanotechnology that make surfaces easier to straighten or ‘self-clean’. One coating, broadly used due to its non-toxicity, chemical stability and functionality for repeated use without the lack of catalytic interactions, is titanium dioxide (tio2).

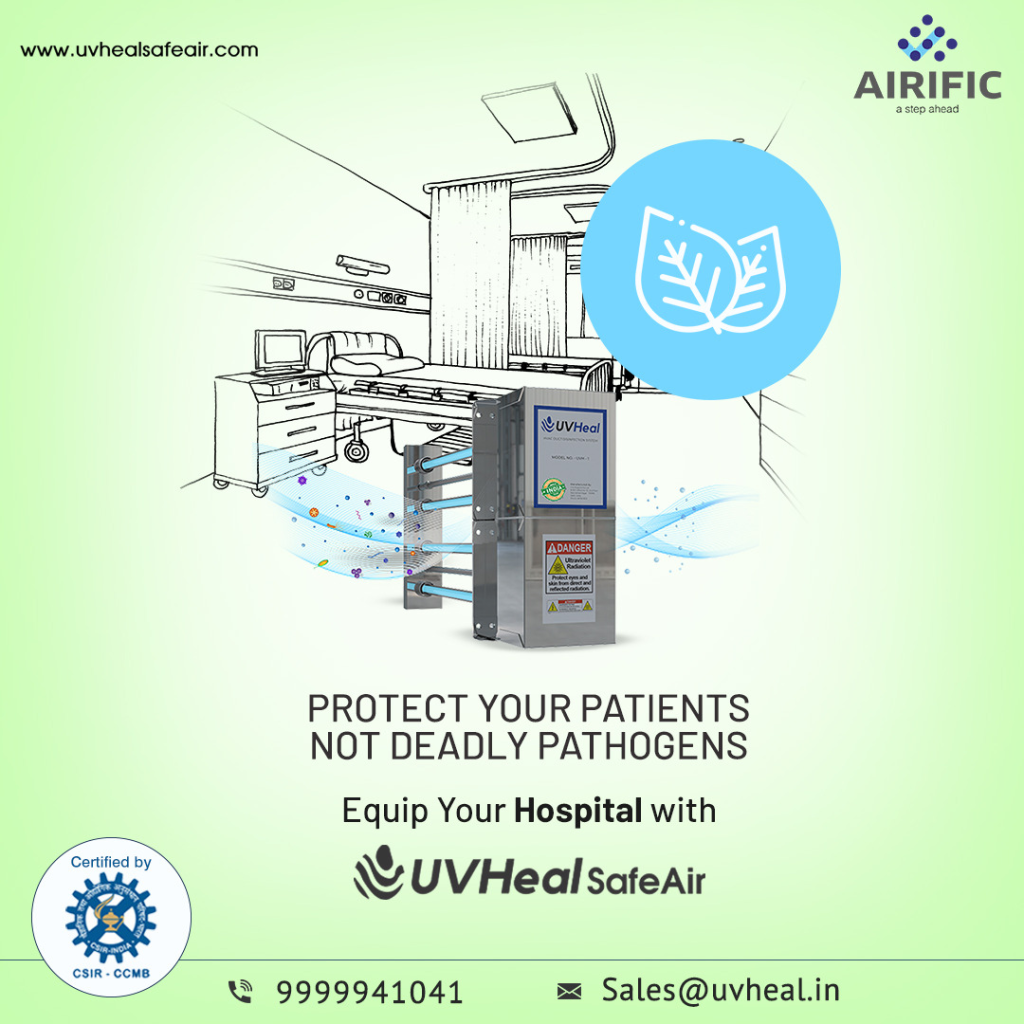

How does UVHeal Safe Air differ from all the above methods?

Airfic

systems are a leading producer of UV structures in India and are widely

recognized throughout various business verticals all over the globe. UVHeal

Safeair, is an UV disinfection system, which offers a whole variety of business ultraviolet

disinfection systems, which consist of custom-made devices that cater to

specific wishes of individual purchasers.